Transportation Solution: TS

The company specializes in engineering services for the deployment of intelligent transportation systems (ITS) or modern mass transit and transportation technology solutions. This includes systems such as Mass Rapid Transit (MRT), Commuter Train (CT), Monorail, and Bus Rapid Transit (BRT), most of which are large-scale projects. Expertise and experience are required to design systems and integrate various complex technologies, including information and communication technology, remote control technology, automatic data collection technology, computer technology, and real-time big data analysis, among others.

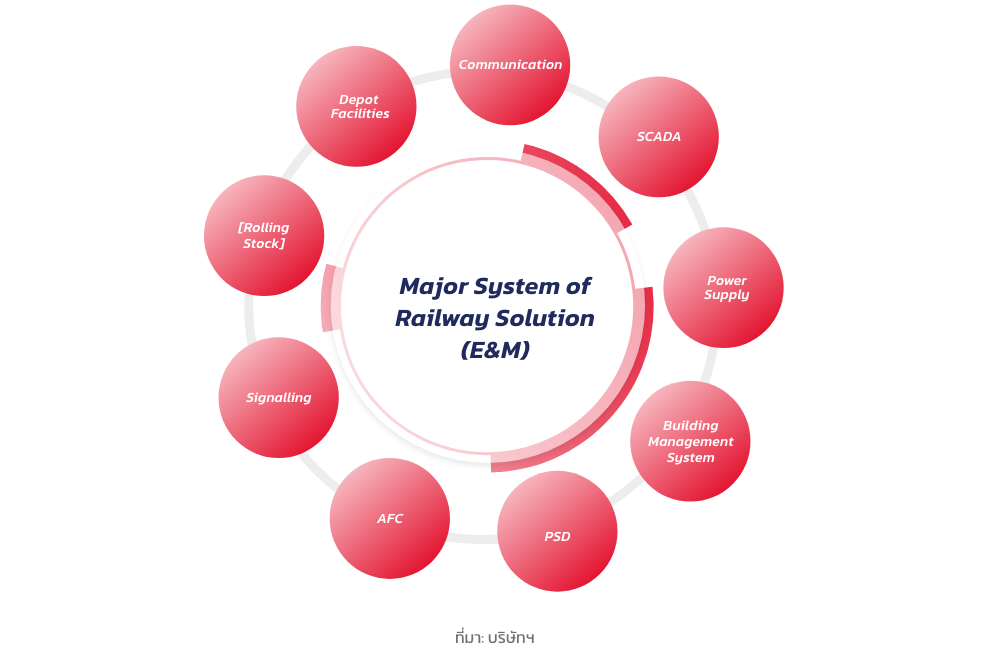

AMR has experience in providing turnkey solutions for operating and maintaining mass transit systems as agreed upon in contracts with clients. This includes consulting, engineering system design and rail operation, procurement of equipment and operational solutions, installation and system integration, maintenance, and training. It covers electrical and mechanical (E&M) systems, which are crucial for efficient and safe rail operation and maintenance.

This encompasses main power supply systems, communication systems, Supervisory Control and Data Acquisition (SCADA) systems, signaling systems, Automatic Fare Collection (AFC) systems, rolling stock systems, building management systems, depot workshop facility management systems, and more.

แผนภาพแสดงงานระบบ E&M สำหรับโซลูชั่นระบบปฏิบัติการการเดินรถและซ่อมบำรุง

The details of the main work system and operational characteristics provided

by the company in implementing mass transit projects are as follows:

The power supply system used in mass transit systems is divided into two main parts: the power supply system for the rail track provided by traction substations, and the power supply system for the stations provided by service substations.

The main components of the power supply system in mass transit systems include:- High Voltage (HV) Electrical System 115kV

- Bulk Substation

- Medium Voltage (MV) Electrical System 22kV/24kV

- Service Substation

- Traction Substation

- Low Voltage (LV) Electrical System 400V

- Main Distribution Board

The company provides services in the design, installation, and control of power supply systems, supplying electrical power to auxiliary power supplies for railway stations and power supply systems for railway traction systems, regardless of voltage levels of 115kV, 24kV, and 22kV.

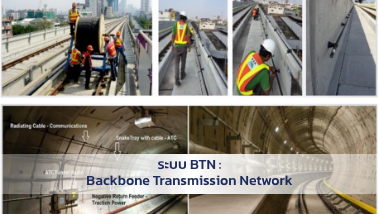

This system is designed to provide channels for communication and data transmission for all systems within the mass transit rail project that require communication and data exchange. It supports various forms of data transmission, including both short-range and long-range communication, transmission via signal cables, and wireless transmission, all in accordance with international standards. It is modern and adaptable to future technologies. Apart from communication systems for railways, the company also has experience in Intelligent Transportation System projects, which include the following systems:

- Backbone Transmission Network (BTN)

- Information Technology System (IT)

- Telephone System (TEL)

- Digital Radio System (DRS)

- Broadband Wireless Data System (BWDS)

- Closed Circuit Television System (CCTV)

- Public Address System (PA)

- Passenger Information Display System (PIDS)

- Master Clock System (MCS)

The company provides comprehensive services including design, installation, and maintenance throughout the warranty period. It has well-equipped support teams specialized in various areas to ensure that customers and users can confidently rely on the efficient and up-to-date operation of the provided systems.

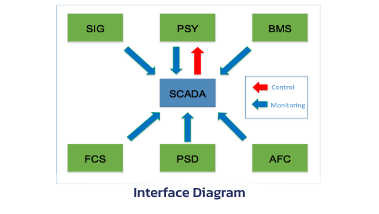

SCADA system is a remote data transmission system used for monitoring, data collection, and controlling various operations remotely. It is convenient for data analysis and enhances flexibility in managing different systems. Digital data communication is facilitated through the telecommunications network. The main components of the SCADA system include:

- Remote Terminal Unit (RTU)

- Communication System

- Control and manage the distribution of electrical power received from the bulk substation to the station, with voltages ranging from 24 KV to 115 KV.

- Control the distribution of electrical power to the power rail for the railway system.

- Monitor and control the operational status of all systems within the service station. Monitoring and controlling all subsystems in the project are done from the Central Control Room (CCR), which includes the following subsystems:

- SIG (Signaling) refers to the system controlling train movement or the automatic signaling system.

- PSY (Power Supply) is the power distribution system from the 3rd Rail or Power Rail to the station's electrical distribution system for various equipment.

- BMS (Building Management System) is the building system including elevators, escalators, fire suppression systems, HVAC systems, building water systems, and building electrical systems.

- FCS (Fixed Communication System) is the communication system comprising network, telephone, clock, radio, closed-circuit television (CCTV), etc.

- PSD (Platform Screen Doors) is the system for platform barrier gates.

- AFC (Automatic Fare Collection System) is the system for automatic fare collection.

In addition, the company has a testing laboratory for SCADA systems before actual installation, as well as provides training for relevant units to ensure confidence that the customer's system can operate continuously and safely.

The signaling system is responsible for controlling and determining the movement direction of train formations, including stopping, slowing down, directing, and ensuring safe and efficient train movement. Even in the event of errors, it still maintains passenger safety.

The major components include:

- Centralized Traffic Control System (CTC): Its main function is to support train operations, plan and manage train schedules, monitor train status, and control the train operation system.

- Computer-based Interlocking System: It controls train operations and the equipment of the automatic signaling system installed in the rail, track, and prevents trains from entering dangerous areas during operation.

- On-board Train Control System: This equipment controls the automatic operation errors of the train and is installed on the train. Its main tasks include monitoring train speed, direction, and position, controlling automatic driving, controlling train spacing, and commanding system operations, brakes, and parking, as well as opening and closing train doors.

- Radio Transmission System (RTS): It is a two-way digital communication network used for tracking and communicating between trains.

The company provides installation and maintenance services throughout the warranty period.

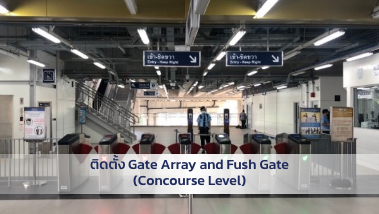

The automatic fare collection system operates on a closed ticketing system, where all passengers must hold valid fare cards to enter the Paid Area of the origin station and exit the Unpaid Area of the destination station at the end of the journey. All data is processed at the Central Computer by the company, which is responsible for designing and installing the following equipment:

- Installation of Ticket Issuing Machines (TIM/TVM)

- Installation of Analyzers/Card Issuers (POS: Point of Sales), used for issuing Smart Pass cards, topping up card values, adding travel passes, and analyzing card status. The automatic fare collection system comprises the following main components:

SCR Room- Central hub for collecting data from Smart Pass systems (Station Data Concentrator: SDC)

- POS analyzers

- AFC-Network

- AFC-Fire Alarm

- AFC-Power Fail

- TIM Room- Installation of Ticket Vending Machines (TVM).

- GATE ARRAY (PAID/UNPAID)- Automatic Gates (AG)

- Flush Gates (FG)

Platform Screen Door (PSD) is an automatic door system commonly installed in modern underground and elevated train stations. This system is responsible for receiving/transmitting open/close commands and monitoring the status of the platform screen doors to ensure passenger safety and prevent individuals or objects from falling onto the tracks. Additionally, it can help control the temperature in stations with air conditioning systems to prevent excessive workload on the air conditioning units. The system interacts with the train control system and signaling system. PSDs can be installed either before or after the operation of the railway system. Currently, PSDs are popularly used in metro systems worldwide.

Types of Automatic Platform Screen Doors- Full Height Platform Screen Doors: These doors are installed as a set of automatic sliding doors (ASD) and fixed glass panels (FGP) from the floor to the ceiling of the platform screen. They often include a motor drive panel (FDP) located above the doors. Full-height PSDs are typically installed in stations with air conditioning systems to control the temperature, helping to reduce electricity consumption.

- Platform Edge Doors: These doors, installed as a set of automatic sliding doors (ASD) and fixed glass panels (FGP), extend from the floor to the maximum height of the train or slightly higher. They also include a motor drive panel (FDP) above the sliding doors. Platform edge doors are commonly installed in stations without air conditioning systems, allowing airflow within the station.

- Half-Height Platform Screen Doors: Also known as Automatic Platform Gates (APG), these doors are installed as a set of automatic sliding doors (ASD) and fixed glass panels (FGP) from the floor to the passenger's head level. They often include a motor drive panel (FDP) located on the side of the sliding doors. Half-height PSDs are typically installed in stations without air conditioning systems or elevated stations where airflow circulation is necessary. Additionally, they offer aesthetic benefits to the station surroundings.

The company provides services for designing, installing, testing, training employees for customers, and maintaining the comprehensive system throughout the warranty period.

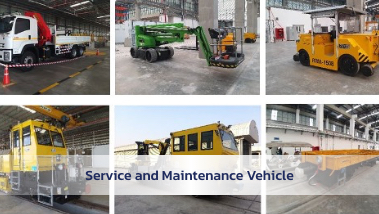

The company provides services in procurement, installation, and testing of systems for equipment used in maintaining the railway systems within the railway maintenance depot. This includes systems such as train lifting systems, disassembly/reassembly equipment, automatic train washing systems, emergency train recovery equipment, maintenance service vehicles, as well as tools for various maintenance tasks related to railway operations.

Moreover, the company has sourced specialized experts both domestically and internationally to support the installation and testing of systems, including theoretical and practical training sessions. Additionally, equipment warranties are provided to ensure compliance with customer requirements.